Home solidworks sheet metal calculating bend allowance bend deduction and k factor who we are and what we do we are canadian experts in 3d and have enabled thousands of companies to aim high with solutions for 3d design data management workflow manufacturing 3d printing.

Multiple bend allowance on sheet metal solidworks.

Bend allowance and bend deduction calculations are methods you can choose to determine the flat length of sheet stock to give the desired dimension of the bent part.

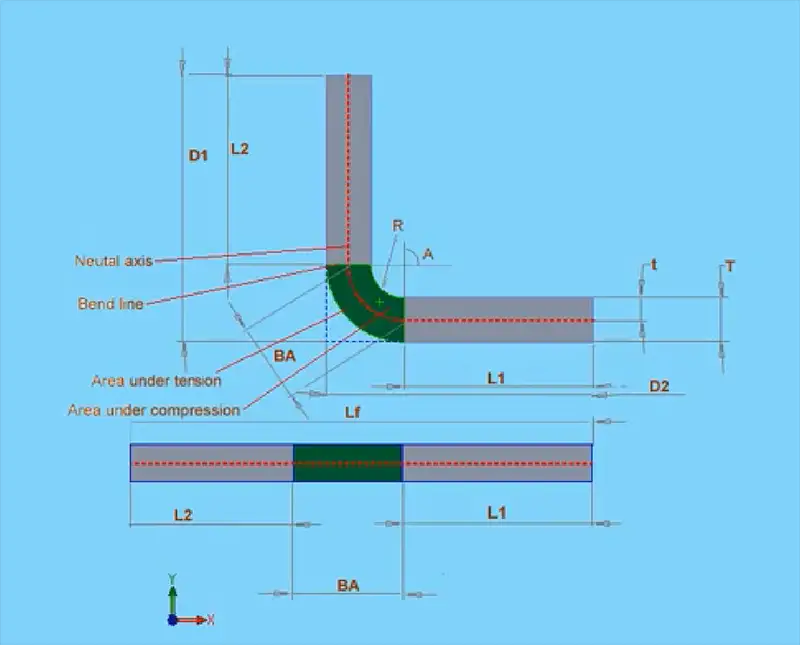

Ba bend allowance.

When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

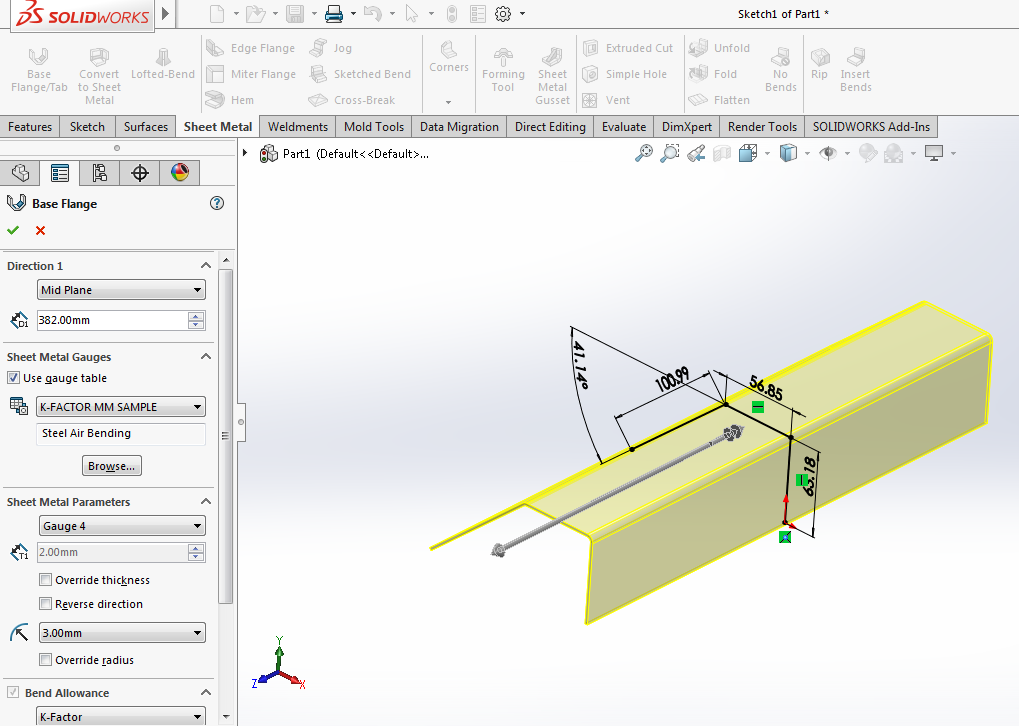

You can specify the bend allowance or bend deduction values for a sheet metal part in a bend table.

It is recommended that you use the excel spreadsheet unless you have legacy bend tables from solidworks 2000 or earlier.

When working in sheet metal we need to be able take a folded sheet flatten it and have an accurate size flat pattern.

Bend allowance and k factor.

Solidworks 2014 sp05 to disable web.

To edit the default bend radius bend allowance or bend deduction or default relief type.

You can also specify k factor values in their own k factor bend tables.

The total length of the flatten sheet is equal to the sum of l1 that s the first length and l2 plus the bend allowance.

Solidworks 2020 sp04 to disable web.

Under sheet metal gauges select use gauge table and select a table.

You can specify an explicit bend allowance or bend deduction for any sheet metal bend by entering the value when you create the bend.

The bend allowance region is shown in green in my diagram this is a region wherein theory all deformation occurs during the bending process.

Bend allowance and bend deduction calculations are methods you can choose to determine the flat length of sheet stock to give the desired dimension of the bent part.

In the featuremanager design tree right click sheet metal and click edit feature.

Understanding the bend allowance and consequently the bend deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated.

As this happens you gain a small amount of total length in your part.

You can specify an explicit bend allowance or bend deduction for any sheet metal bend by entering the value when you create the bend.

In solidworks this is achieved by selecting the relevant bend allowance options in the sheet metal tool.